Introduction

In today's fast-paced construction landscape, precast boundary walls have emerged as a smart alternative to conventional brick or stone fencing. Whether for a residential villa, a commercial complex, or an expansive industrial unit, these factory-made wall panels offer a compelling blend of durability, aesthetics, cost efficiency, and speed.

What Are Precast Boundary Walls?

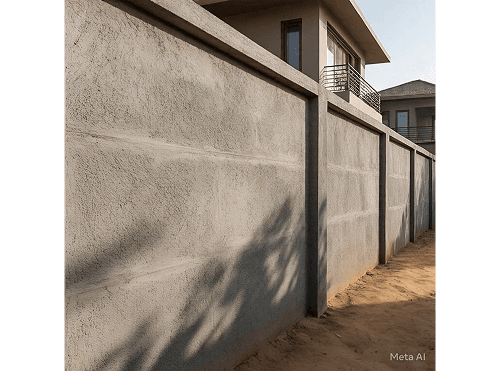

Precast boundary walls are modular concrete walls manufactured in a controlled factory environment using high-quality molds, reinforcement, and concrete mix. These panels are then transported to the construction site and installed on pre-laid foundations or columns.

Unlike traditional brick walls which are built brick-by-brick on-site, precast walls are pre-engineered, pre-tested, and pre-approved ensuring consistency and strength with significantly reduced installation time.

Why Precast? The Benefits at a Glance

Let's dive deep into the many advantages that precast boundary walls bring to the table:

- •Speedy Installation

Precast walls can be installed up to 5 times faster than traditional walls. Since the panels are ready-made, they only need to be fixed on-site using simple mounting techniques. This dramatically reduces project timelines and labor costs.

For large commercial or industrial projects, this speed translates into massive cost savings and quicker project turnarounds.

- •Superior Strength and Durability

Manufactured under controlled conditions using high-grade materials and steel reinforcement, precast panels are highly resistant to weather, corrosion, pests, and wear.

They have a longer lifespan and require minimal maintenance compared to brick walls, which are prone to cracks, erosion, and moisture-related issues.

- •Cost-Effective in the Long Run

While the initial cost of precast walls may seem comparable or slightly higher than traditional walls, the long-term savings are substantial:

- •Reduced labor charges

- •No need for plastering or frequent painting

- •Lower repair and maintenance costs

- •Lesser wastage during construction

- •Enhanced Security

Security is a top priority for any property owner. Precast boundary walls offer:

- •Greater height options (up to 10 ft or more)

- •Robust concrete thickness

- •Optional integration with razor wires, electric fences, or CCTV poles

This makes them an ideal choice for industrial zones, data centers, warehouses, gated communities, and sensitive government facilities.

Aesthetic Appeal

Modern precast walls are available in a variety of textures, colors, and finishes. From stone-like textures to wood-patterned surfaces, clients can choose designs that blend seamlessly with their property's theme.

In fact, custom branding or logos can even be embedded into the wall panels for corporate premises.

Environmentally Friendly

Since precast walls are manufactured with precision and minimal waste, they are a more sustainable option than on-site brick construction, which typically involves high material wastage and energy usage.

Also, their long life and low maintenance reduce the environmental impact over the structure's lifetime.

Easy Relocation and Expansion

In case you need to relocate or expand your property, precast boundary panels can be disassembled and reused, something that's nearly impossible with traditional walls.

This makes them especially appealing to temporary project sites, such as construction zones, mining areas, or temporary warehouses.

Use Cases of Precast Boundary Walls

Precast walls have seen adoption across a wide range of industries and sectors:

- •Residential

Villas and farmhouses, Gated societies, Perimeter fencing for plots - •Commercial

Office parks, Shopping malls, Showrooms - •Industrial

Factories, Warehouses, Power plants, Water treatment plants - •Institutional

Schools and universities, Hospitals, Government offices - •Infrastructure & Utilities

Airports, Railways, Highway rest areas, Substations and telecom facilities

How Are Precast Walls Installed?

The process is quick and efficient:

- •Site Preparation

Levelling the area and creating a solid base or foundation for support pillars. - •Column Placement

RCC columns with grooves are fixed at calculated intervals. - •Panel Placement

Precast panels are slid into the grooves between columns and secured. - •Finishing Touches

Optional plastering, painting, or aesthetic treatments are added.

Customization Options Available

Modern precast technology allows for a high level of customization:

- •Panel thickness and height

- •Decorative textures and surface finishes

- •Color coating and anti-graffiti layers

- •Integrated security features (cameras, sensors, wiring conduits)

Challenges & Considerations

While precast boundary walls are generally advantageous, there are a few factors to consider:

- •Transportation logistics

Large panels need proper transport and handling. - •Initial planning

Accurate measurements and design layouts must be finalized upfront. - •Skilled labor

Installation needs a trained team to ensure perfect alignment.

However, partnering with a reputed manufacturer ensures these challenges are well managed.

Final Thoughts: A Smarter Future with Precast Walls

As the construction industry moves towards faster, cleaner, and smarter solutions, precast boundary walls are becoming the preferred fencing option across the globe. Whether you're looking to secure a luxury estate, define a commercial zone, or protect an industrial asset—precast offers strength, security, and style in one smart package.

With endless design possibilities and robust engineering, precast is not just a product—it's a long-term investment in safety, efficiency, and sustainability.

Looking for a reliable precast wall solution?

Partner with a trusted manufacturer to explore custom designs, installation guidance, and site-specific recommendations. Contact us to learn more about it.